The Beauty of Silence

28 september 2020

We all know that person that decides to mow his lawn at 8 o’clock on a Sunday morning

Mechanical compressors are that person when it comes to hydrogen refuelling stations in populated areas. The current equipment that compresses hydrogen to the required pressures produces a constant noise. In most countries this is the reason not to place Hydrogen Refuelling Stations in these densely populated areas.

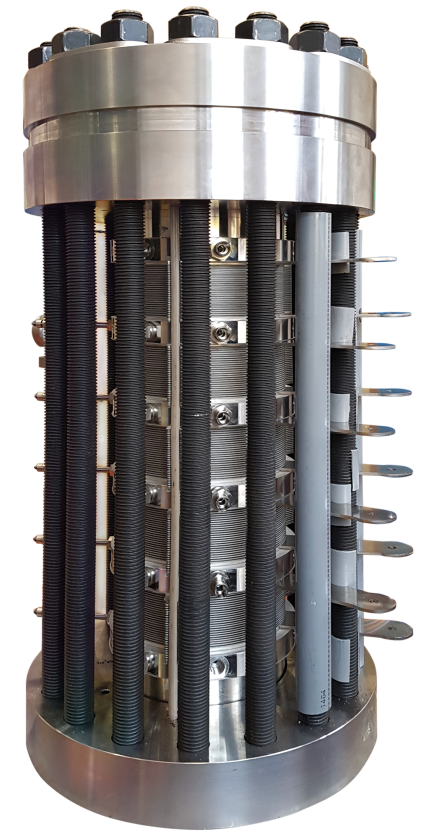

Though, not all hydrogen compressors have moving parts. Electrochemical Hydrogen Compression does not require any moving parts and is therefore completely silent.

What do we mean by no moving parts

The fact that the electrochemical compressor has no moving parts is also advantageous because it avoids wearing of parts. This is one of the reasons why the Electrochemical Hydrogen Compressors (EHC) require virtually no maintenance. The absence of moving parts contributes significantly to the reduction of maintenance costs and the prevention of damage, when compared to mechanical compressors.

Safety and efficiency

In some situations, mechanical compressors cannot meet the safety and reliability criteria necessary for their use. The main reason for this is that hydrogen easily leaks through the dynamic seals of mechanical compressors. This sealing problem inevitably implies a potential safety risk and a reduction in the potentially achievable efficiency.

Complete silence

The fact that hydrogen in EHC systems is pressurized through static Proton Exchange Membranes – that operate under an electrical potential – enables a smooth (pulse free) compression and therefore guarantee a completely silent operation. This means there are no License-to-Operate issues to be expected when operating EHC in residential areas.

To sum up: EHC systems are reliable, fully silent, solid state hydrogen compressors with minimum maintenance requirements pressurizing hydrogen in a single stage. Therefore, EHC systems provide excellent solution for filling the buffer tanks in Hydrogen Refuelling Stations in residential areas.

Reference:

- https://link.springer.com/article/10.1007/s41918-020-00077-0